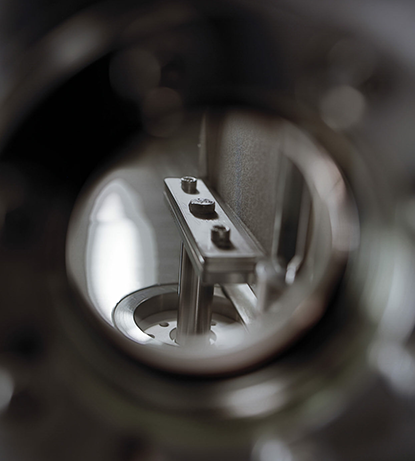

Electron Beam Melting (EBM) is an advanced metal additive manufacturing (AM) technology that utilizes a high-energy electron beam to fuse metal powder layer by layer. This technology is particularly suitable for high-performance, lightweight, and complex metal parts, making it a key solution for industries requiring exceptional material properties.

Electron Beam Melting Technology

Pushing the boundaries of metal 3D printing with high-strength, high-precision

What is Electron Beam Melting (EBM)?

Start Your Journey With Us

Have a question or a project in mind?

Our team is ready to collaborate and bring your ideas to life.

How Does EBM Work?

EBM technology operates under a controlled vacuum environment to ensure purity and precision:

Key Benefits of EBM Technology

Industries & Applications of EBM

EBM technology is widely used in industries demanding high-performance metal components, including: