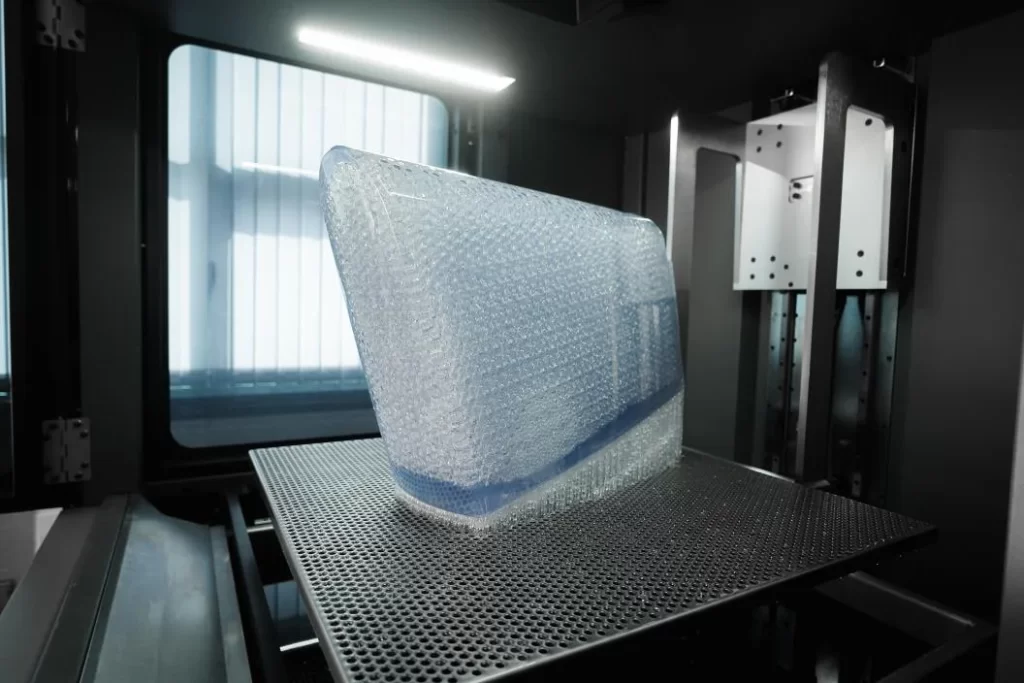

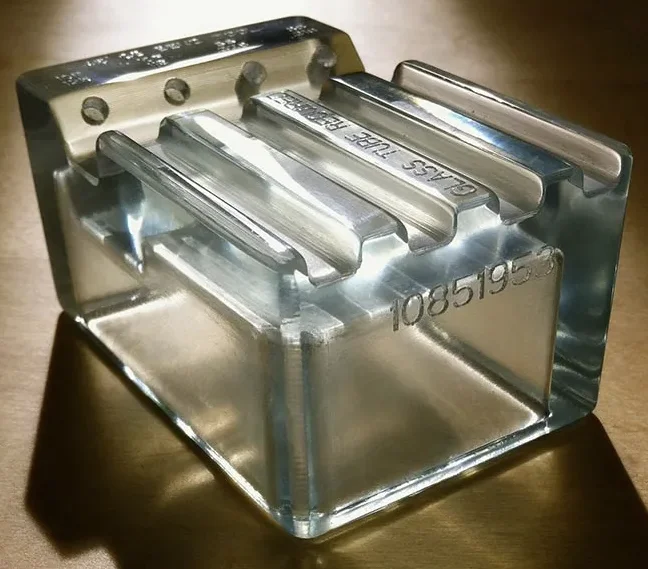

Stereolithography (SLA) is one of the earliest and most precise resin-based 3D printing technologies. It uses a UV laser to cure liquid photopolymer resin, layer by layer, to create highly detailed and smooth parts.

SLA Technology

Superior surface quality in high-volume, large-part production

What is SLA Technology

Start Your Journey With Us

Have a question or a project in mind?

Our team is ready to collaborate and bring your ideas to life.

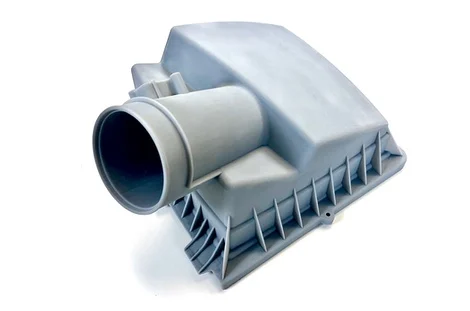

Why Stereolithography (SLA) 3D printed parts?

Stereolithography (SLA) is one of the most precise and versatile 3D printing technologies, ideal for high-detail prototypes and functional parts. Using a UV laser to cure liquid resin, SLA produces ultra-smooth surfaces, intricate details, and high accuracy, making it a top choice for many industries.