With over 30 years of experience, infoTRON has established itself as a trusted partner for leading consumer goods, automotive, aerospace, and defense companies, delivering high-quality design, engineering, and manufacturing solutions. Our approach is holistic and interdisciplinary, integrating the latest advancements in digital design, simulation and additive manufacturing to create efficient, cost-effective, and high-performance products.

Product Design & Engineering

Taking projects from initial concept ideation to

full-scale manufacturing.

Innovating Industries,

Transforming Possibilities

Start Your Journey With Us

Have a question or a project in mind?

Our team is ready to collaborate and bring your ideas to life.

We provide end-to-end support across all phases of product development, offering:

Industrial Design

Where creativity meets functionality! Our industrial design team works on developing aesthetically appealing, ergonomic, and user-friendly designs that align with brand identity and market expectations. Using human-centered design principles, we ensure that products are visually striking, highly practical, and manufacturable.

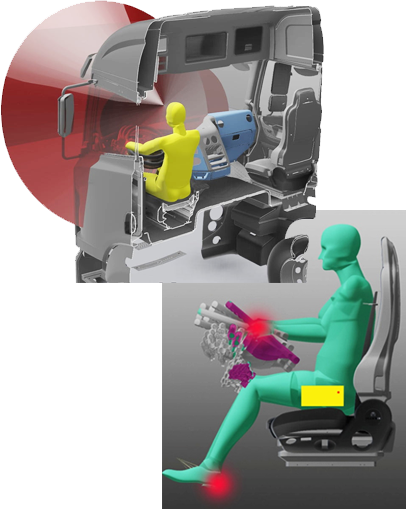

Ergonomics

Designing for comfort, safety, and performance! Our ergonomics team focuses on creating products, workspaces, and systems that enhance user well-being and efficiency. By applying human-centered design principles and ergonomic analysis, we ensure that every solution minimizes physical strain, improves posture, and maximizes productivity. From workplace ergonomics to product usability, our approach promotes health, comfort, and user satisfaction in every interaction.

Our ergonomics solutions allow for:

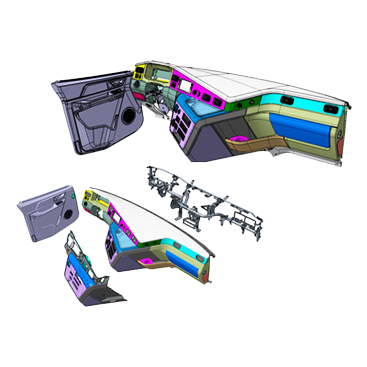

Class A Surface Modeling Application Areas

Class A Surface Modeling is a high-precision surface modeling technique used to achieve perfect aesthetic quality, smooth transitions, and manufacturability for products that require visual excellence and aerodynamic performance. This process is essential in industries where design and functionality merge, ensuring flawless reflections, curvature continuity, and seamless part integration.

Mechanical Design

Mechanical design is at the core of product development, ensuring that components and systems are functional, durable, and manufacturable. By leveraging advanced CAD tools, engineering analysis, and material selection, mechanical design plays a critical role in industries such as automotive, aerospace, consumer electronics, and industrial equipment.

Mould Design

Comprehensive solutions for high-quality manufacturing! We provide comprehensive mold design solutions tailored to your manufacturing needs. Whether you’re producing complex parts or high-precision components, our experienced design team ensures that every mold is optimized for efficiency, quality, and durability.

DfAM

When products designed for traditional manufacturing are produced with 3D printing, they often require more time, material, and cost than necessary. That’s where our Design for Additive Manufacturing (DfAM) team steps in! Our expert team redesigns and optimizes your products for additive manufacturing, ensuring lighter parts with the same strength, cost-efficient production, faster manufacturing cycles, and minimal material waste.

With over 30 years of experience, infoTRON delivers high-performance DfAM solutions to industries across Europe, helping businesses achieve better, smarter, and more sustainable production.

Engineering Simulators

Visualize, analyze, and predict—before you build! Engineering simulation uses advanced software to test and validate the behavior of products and systems while they are still in development. By simulating real-world conditions, we help you evaluate performance, durability, and efficiency in a virtual environment.