Interactive Virtual Mockup Assembly (iVIMA) is a project developed by infoTRON in collaboration with RENAULT, supported under the EUREKA E!3178 initiative. The project aims to enhance virtual assembly processes in the automotive industry using virtual reality (VR) and augmented reality (AR) technologies. iVIMA enables the simulation of vehicle assembly operations in a digital environment, reducing the need for physical prototypes and improving the efficiency of design and production processes. It also facilitates collaboration between teams across different locations within a shared virtual workspace, increasing global coordination and productivity.

Interactive Virtual Mockup Assembly (iVIMA) is a project developed by infoTRON in collaboration with RENAULT, supported under the EUREKA E!3178 initiative. The project aims to enhance virtual assembly processes in the automotive industry using virtual reality (VR) and augmented reality (AR) technologies. iVIMA enables the simulation of vehicle assembly operations in a digital environment, reducing the need for physical prototypes and improving the efficiency of design and production processes. It also facilitates collaboration between teams across different locations within a shared virtual workspace, increasing global coordination and productivity.

Project Website: https://infotron.com.tr/en/

The Comprehensive Automobile Research and Development Simulator (CARDS) is an automotive simulation platform developed by infoTRON under the EUREKA E!1924 initiative in collaboration with RENAULT. This project utilizes immersive simulation technologies to support automotive design and development processes. CARDS enables the virtual testing of vehicle dynamics, ergonomics, and user interactions, and is integrated with VR/XR technologies. Supported by EUREKA.

The Comprehensive Automobile Research and Development Simulator (CARDS) is an automotive simulation platform developed by infoTRON under the EUREKA E!1924 initiative in collaboration with RENAULT. This project utilizes immersive simulation technologies to support automotive design and development processes. CARDS enables the virtual testing of vehicle dynamics, ergonomics, and user interactions, and is integrated with VR/XR technologies. Supported by EUREKA. Supported by FP7 7.Çerçeve Programı. The DirectSpare project proposes a solution to the increasing demand for spare parts storage, driven by shorter product life cycles, faster time-to-market, and growing regulatory requirements. By utilizing Rapid Manufacturing (RM) technology, it enables on-demand, localized production of spare parts, eliminating the need for large warehouses and reducing costs, logistics complexity, and waste. This approach offers significant advantages, including cost savings in warehousing and production, environmental benefits by reducing excess manufacturing, improved competitiveness for SMEs, localized job creation, and the ability to enhance and customize spare parts before production.

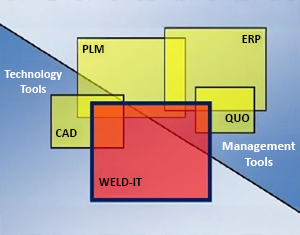

Supported by FP7 7.Çerçeve Programı. The DirectSpare project proposes a solution to the increasing demand for spare parts storage, driven by shorter product life cycles, faster time-to-market, and growing regulatory requirements. By utilizing Rapid Manufacturing (RM) technology, it enables on-demand, localized production of spare parts, eliminating the need for large warehouses and reducing costs, logistics complexity, and waste. This approach offers significant advantages, including cost savings in warehousing and production, environmental benefits by reducing excess manufacturing, improved competitiveness for SMEs, localized job creation, and the ability to enhance and customize spare parts before production. Supported by FP7 7.Çerçeve Programı. The Weld-IT project aims to develop a knowledge-based assistive tool to help welding companies price, plan, and manage welding projects more efficiently. While welding is critical in many industries, current cost estimation methods rely heavily on manual calculations by experts, making the process time-consuming and costly. Weld-IT will automate and optimize welding project pricing by considering key factors such as project requirements, customer preferences, manufacturing capabilities, resource allocation, and industry standards. This tool will enhance flexibility, reduce costs, and improve competitiveness by enabling faster and more accurate decision-making in welding project management.

Supported by FP7 7.Çerçeve Programı. The Weld-IT project aims to develop a knowledge-based assistive tool to help welding companies price, plan, and manage welding projects more efficiently. While welding is critical in many industries, current cost estimation methods rely heavily on manual calculations by experts, making the process time-consuming and costly. Weld-IT will automate and optimize welding project pricing by considering key factors such as project requirements, customer preferences, manufacturing capabilities, resource allocation, and industry standards. This tool will enhance flexibility, reduce costs, and improve competitiveness by enabling faster and more accurate decision-making in welding project management. Supported by Eureka Smart. The project aims to develop cost-effective EDM electrodes using polymer-based additive manufacturing methods, specifically Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM). Traditional EDM electrode production using subtractive machining is time-consuming and expensive, whereas additive manufacturing can significantly reduce production time (24-48 hours), material waste, and costs. To enhance conductivity, commonly used polymers (ABS, PA, PLA) will be reinforced with carbon-based additives (graphite, carbon nanotubes, nano carbon fiber). Electrodes will be further improved through PVD or electrolysis coating. The project will focus on testing and optimizing highly conductive polymer-based EDM electrodes for industrial applications.

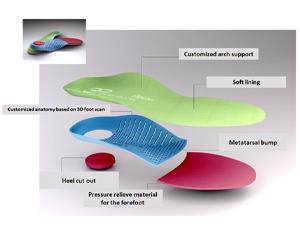

Supported by Eureka Smart. The project aims to develop cost-effective EDM electrodes using polymer-based additive manufacturing methods, specifically Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM). Traditional EDM electrode production using subtractive machining is time-consuming and expensive, whereas additive manufacturing can significantly reduce production time (24-48 hours), material waste, and costs. To enhance conductivity, commonly used polymers (ABS, PA, PLA) will be reinforced with carbon-based additives (graphite, carbon nanotubes, nano carbon fiber). Electrodes will be further improved through PVD or electrolysis coating. The project will focus on testing and optimizing highly conductive polymer-based EDM electrodes for industrial applications. Supported by EuroStars. The RapidOrtez project aims to develop an additive manufacturing-based production system for the mass customization of medical foot orthotics, making them both personalized and widely accessible. Based on a 3D scan of the patient’s foot, a customized insole will be designed to meet individual needs through parameterized modeling. Additive manufacturing techniques will be utilized to produce the insoles, and post-processing steps will be applied to ensure that their mechanical properties align with the patient’s prescription requirements.

Supported by EuroStars. The RapidOrtez project aims to develop an additive manufacturing-based production system for the mass customization of medical foot orthotics, making them both personalized and widely accessible. Based on a 3D scan of the patient’s foot, a customized insole will be designed to meet individual needs through parameterized modeling. Additive manufacturing techniques will be utilized to produce the insoles, and post-processing steps will be applied to ensure that their mechanical properties align with the patient’s prescription requirements. Supported by ERASMUS+, this project addresses the gap between the investment in CNC technologies and the expected productivity, precision, and complexity in the woodworking and furniture industries. A key reason is the insufficient training of CNC operators. This two-way initiative aims to develop an on-the-job training curriculum based on andragogical principles, enhancing operators’ ability to fully utilize CNC technologies. It also promotes lifelong learning, problem-solving via e-media, and equips operators with essential computer literacy and CAD skills to better interact with machines and designers.

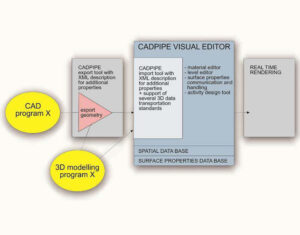

Supported by ERASMUS+, this project addresses the gap between the investment in CNC technologies and the expected productivity, precision, and complexity in the woodworking and furniture industries. A key reason is the insufficient training of CNC operators. This two-way initiative aims to develop an on-the-job training curriculum based on andragogical principles, enhancing operators’ ability to fully utilize CNC technologies. It also promotes lifelong learning, problem-solving via e-media, and equips operators with essential computer literacy and CAD skills to better interact with machines and designers. Supported by FP6 6. Çerçeve Programı. The CADPIPE project aims to develop efficient, automated tools to streamline the transition from 3D CAD design to high-quality real-time visualization, reducing costly and time-consuming manual work. By optimizing data conversion pipelines and minimizing unnecessary details, CADPIPE will enhance compatibility between CAD, visualization and real-time rendering environments. The project seeks to eliminate the need for separate format conversion tools, improve data preservation, enable basic interactive and physical behavior properties in 3D models and enhance real-time rendering performance, ensuring a seamless and efficient workflow for industry applications.

Supported by FP6 6. Çerçeve Programı. The CADPIPE project aims to develop efficient, automated tools to streamline the transition from 3D CAD design to high-quality real-time visualization, reducing costly and time-consuming manual work. By optimizing data conversion pipelines and minimizing unnecessary details, CADPIPE will enhance compatibility between CAD, visualization and real-time rendering environments. The project seeks to eliminate the need for separate format conversion tools, improve data preservation, enable basic interactive and physical behavior properties in 3D models and enhance real-time rendering performance, ensuring a seamless and efficient workflow for industry applications.