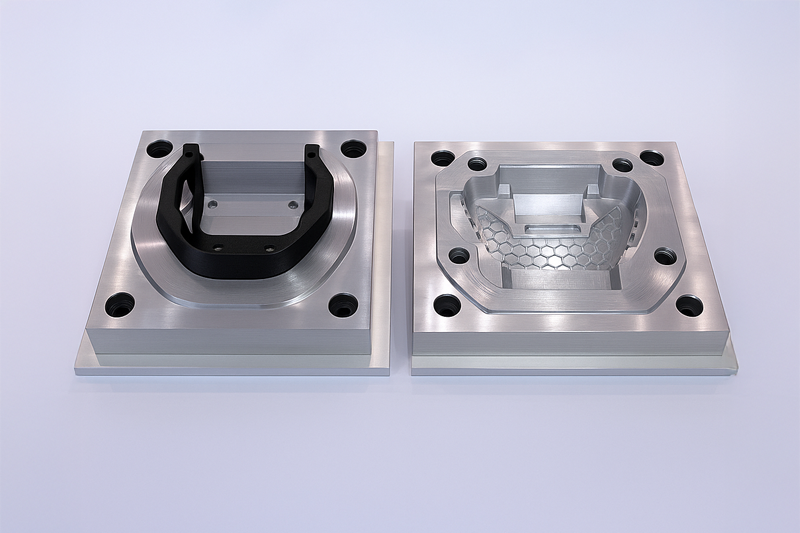

We All Know About Steel And Aluminum Injection Tooling – We Can Support You With These Tools As Well As Rapid Hybrid Tooling.

Rapid Injection Molding

Reduce Mold Costs & Accelerate Design Validation with Affordable Prototype Tooling

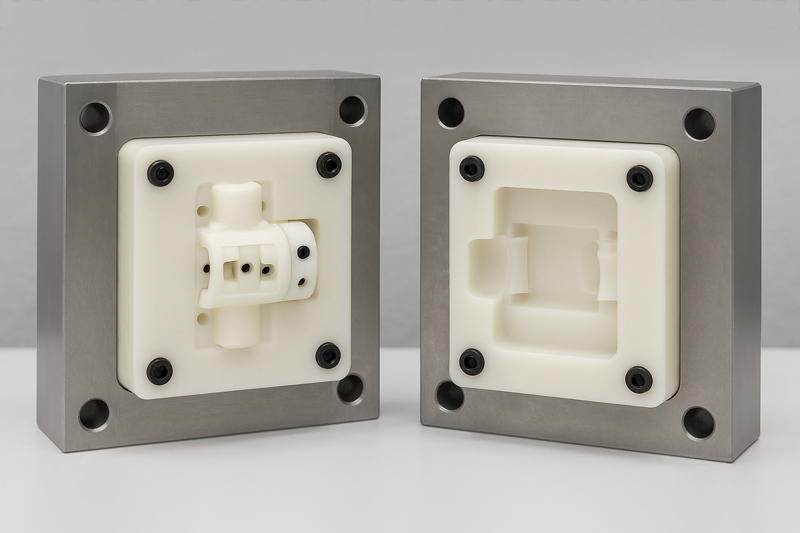

Rapid Hybrid Tooling

Rapid Hybrid Tooling is an innovative manufacturing approach that combines high-tech 3D printing with traditional plastic injection molding to deliver cost-effective, high-quality, and fast production of end-use parts. This method leverages the speed and design flexibility of additive manufacturing while maintaining the durability and scalability of injection molding.

At infoTRON, we produce high-performance mold cores using four advanced manufacturing technologies: FDM, PolyJet, Metal Laser Sintering, and CNC Machining. By combining these cutting-edge methods, we deliver precision-engineered mold cores tailored to your production needs.

Once the mold cores are produced, they are integrated into traditional CNC-machined mold sets, allowing you to test with real materials before full-scale production. This hybrid approach ensures faster development, cost efficiency, and high-quality end-use parts.

Benefits of Hybrid Tooling

Why to choose use for Rapid Injection Molding?

Start Your Journey With Us

Have a question or a project in mind?

Our team is ready to collaborate and bring your ideas to life.