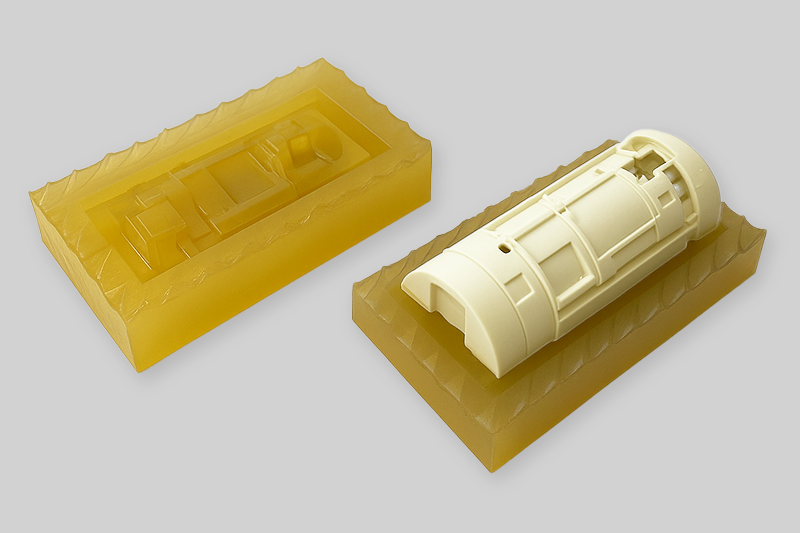

Vacuum casting is a versatile and cost-effective manufacturing process used to produce high-quality plastic and rubber parts. It involves creating silicone molds from a master model and using them to cast identical parts with excellent surface finish and fine details. This method is ideal for prototyping and small-batch production while closely mimicking the properties of injection-molded parts.

Vacum Casting

With our vacuum casting expertise, we provide fast, reliable, and high-quality part production to meet your needs.

What is Vacuum Casting?

Start Your Journey With Us

Have a question or a project in mind?

Our team is ready to collaborate and bring your ideas to life.

Why Choose Vacuum Casting?